Pump Guide

- Quick Links

> Alignment of the pump - Click here

> Understanding pump recirculation – Click here

> Slip Factor – Click Here

> Velocity Triangle – Click Here

> Restoring Pumps with Coatings – Click here

> Centrifugal pump vs. rotary pump - Click here

> Centrifugal pump efficiency - Click here

> API material classification - Click Here

> Arrangement 1, 2, and 3 type seal – 00 - Click Here

> Arrangement 1, 2, and 3 type seal – 01 - Click Here

> Cryogenic Pump - Click Here

> Pump Power - Click Here, Example of Power calculation

> Installed power - Click Here

> Friction Loss - Click Here

> Affinity Law - Click Here

> Bernoulli’s Principle - Click Here

> Hydrodynamic Lubrication - Click Here

> Centrifugal pump performance curve - Click Here

> Pump NPSH - Click Here + Click Here

> Barometer - Click Here

- Frequently used words

> LDAR - Leak Detection and Repair

> HRVOC - Highly Reactive Volatile Organic Compounds

> LOI - Letter of Indent

> CIN - Customer Identification Number

> GRN - Goods Receive Note

> LR - Laurie Receipt

> TPI - Third-Party Inspection

> PDI - Pre-Dispatch Inspection

> LC - letter of Credit

> CDS - Certified Data Sheet

> VAF – Verification Audit Form

> NACE - National Association of Corrosion Engineers

> PSS - Pump Selection System

- Key Points

> Pumps are in series - High Head

> Pumps are in Parallel - High Flow

> API region preferred for pump operating - 70 to 120%

> Flinger used - above 45 degrees temperature - we avoid using Inpro there

> Below BEP - Recirculation losses are higher

> Cut water - Avoid Recirculation

> Max. Allowable bending for Shaft - 0.005"

> Acceptable Runout for shaft - 0.001"

> Full assembled rotor allowable - runout 0.001"

> Impeller Wear ring installation - Heating

> Case Wear ring installation – Cooling

> RPM = 120 x (Frequency / Motor Pole)

> Head = 2.31 x Pressure / Specific Gravity

> Specific Gravity = Density of the part / Density of reference part

> Water @ 72° F (22° C) = Specific Gravity = 1

> Gauge Pressure - Pressure above/below atmosphere pressure

> Absolute Pressure - Pressure above absolute vacuum

> Bare pump - Pump without Auxiliary Piping and motor

> Impeller having small discharge - High Head and Low Flow

> Volute width (b3) is made 1.6 to 2.0 times the impeller width (b2)

> Tap thread length - 1.5 x Thread Diameter

> Holes - 1A/2A/3A - External Threads, 1B/2B/3B - Internal Thread

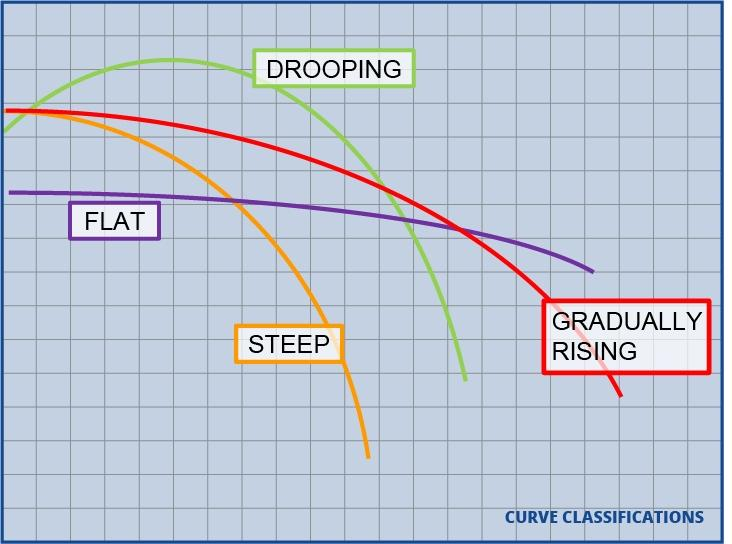

> As specific speed increases, the H-Q curve becomes more stable.

> Pumps with unstable curves will develop more Head and be more efficient than their continuously rising counterparts.

- Ambient temperature

Ambient temperature is the air temperature of an environment

or object.

In computing, ambient temperature refers to the air temperature

surrounding computing equipment.

This measurement is crucial for equipment

function and longevity

- Drooping

- What is Shutoff

The shutoff head is the head a pump will develop when operating against a closed discharge valve. The terms dead-heading and zero flow are sometimes used interchangeably with the term shutoff.

In some pumping systems, in order to purge all air out of the piping system or to minimize pressure fluctuations within the piping, it is necessary to start and stop a centrifugal pump against a closed discharge valve. During this scenario, the pump will be required to operate at shutoff for a period of time that is usually no more than 30 seconds long.

The

duration of this cycle should be determined in coordination with the pump

manufacturer, and continuous operation at shutoff should be carefully avoided.

- Suction-lift configuration

- Centrifugal Pumps Must be Primed

Centrifugal pumps can’t pump air,

Since they operate by imparting velocity to a liquid, they must be filled with liquid in order to operate.

However, there is a special type of centrifugal pump that can evacuate the air from its suction line. This type of pump is called a self-priming pump.

- How do Self-Priming Pumps Work?

Running a self-priming pump while empty will result in a mechanical seal failure and may cause damage to other internal components.

Self-priming pumps are designed to retain the amount of water needed for self-priming. So once a self-priming pump has run once, it will automatically contain enough water to self-prime.

However, when starting an empty self-primer, the pump must be primed manually.

- Unit of Kinetic viscosity – SSU

- Viscosity

- Horsepower

- Specific Speed

- Suction Specific Speed

- Circular volute design

- Stud

S - Allowable bolt stress (psi)

Ar - Root area of bolt thread (sq. in.)

- Functions of pump parts

- Inertia

- Investment Casting vs. Sand Casting

- Impeller Underfile

- Types of Wear

- Difference between Cavitation and Flashing

Flashing: The phenomenon of vapor formation due to a pressure lower than vapor pressure is the same in flashing. The main difference is, flashing is a desirable process done purposefully in a flash tank to use the resulting vapor elsewhere in process plants, while cavitation is an undesirable process, resulting in physical wear of machinery.

- Repeller/Expeller

- Why is the discharge pipe diameter of a centrifugal pump smaller than the suction pipe?

if you are to check the total head at the inlet to be more than the vapor pressure head, so as to prevent boiling of liquid → cavitation,

then you need to minimize the frictional head loss there.

head loss due to friction= h = [f l v^ 2] / 2 g D

YOU CERTAINLY NEED TO CONSIDER WHAT YOU ARE PUMPING….!

- Avoid confusion: head vs pressure

Head is fluid-independent, that is, regardless of the fluid's relative density, the pump will lift it to the same height. Therefore, it does not matter whether the fluid is water or heavy sludge.

Pressure, on the other hand, is fluid-dependent and is affected by gravity. Therefore, the same head will generate a different pressure depending on the fluid's relative density.

A pump, designed for a 60 Hz power supply, tested with a 50Hz supply, what will be the effect on efficiency and NPSHr?

Ans.

Motor Speed = (120 x f) / P

where, f = frequency

P = Number of poles

A 4 pole, 50 Hz motor = 1500 rpm

With a 60 Hz motor = 1800 rpm

Going by the pump’s Q-H performance curves,

- Lower speed (lower frequency), gives reduced pump head and reduced efficiency.

- Similarly, at a lower speed, the NPSHr also decreases.

Question

A. Change in operating speed

B. Trimming the impeller diameter

C. A and B both

D. Neither A nor B

Ans.

In principle, Ns for a particular impeller remains the same.

Specific speed calculation - Flow and head value to be considered are at BEP with maximum impeller dia.

Even if you don't consider that, with the different speeds and impeller dia, the BEP flow and head will also change. But, ultimately Ns will remain the same.

- Pump P1 - Flow 500 m3/hr @50 m head

- Pump P2 - Flow 50 m3/hr @500 m head

pump head is very easy to define and understand, it is the height at which a pump can raise fluid up against gravity. it is expressed in m or ft.

A compressor head is a form of energy that can be expressed in 2 different components.

1. Energy required to compress a unit amount of mass at a given pressure ratio.

2. Energy required to raise unit mass by a certain height.

it is expressed in kJ/kg.

[2] Determination of cavitation occurrence / NPSHr test is an interpreted test (3% head drop criterion). For cryogenic fluids, I have seen head drop consideration for NPSHr determination to be 10%.

[3] Cavitation occurs not only for Centrifugal pumps but is applicable for other types as well. In reciprocating pumps, NPSH consideration is even more severe (due to Acceleration head loss).

[4] NPSHr is dependent on fluid properties as well. What we see on the pump curves are values for water. NPSHr for other fluids is actually somewhat different.

Comments

Post a Comment

Feel free to share your valuable feedback!